Introduction

The drum sieve is composed of five parts: a circular drum, a frame, a funnel, a reducer, and an electric motor. After the crushed stones enter the drum, they are screened by the centrifugal force and bouncing effect caused by the rotation of the drum. The screened materials pass through different mesh screens one by one. Stones of different specifications are screened out and then fall through the funnel into the belt conveyor and are sent to the finished product storage area. On one hand, they are screened as the drum rotates, relying on the centrifugal force and bouncing effect of the drum to screen the materials. On the other hand, the larger-sized stones flow forward along the slope of the drum and are gradually screened out through different mesh screens. The smaller stones are screened out and fall into their respective funnels, and then are transported out by manual means or sent to the finished product storage area by gravity.

material

Working Principle

The drum sieve machine mainly consists of a motor, a reducer, a drum assembly, a frame, a sealing cover, and an inlet and outlet opening. The drum assembly is inclinedly installed on the frame. The motor is connected to the drum assembly through a coupling via the reducer, driving the drum assembly to rotate around its axis. When the material enters the drum assembly, due to the inclination and rotation of the drum assembly, the materials on the screen surface will be flipped and rolled, allowing the qualified materials (the products below the screen) to be discharged through the screen mesh on the outer circle of the drum, and the unqualified materials (the products above the screen) to be discharged from the end of the drum. Due to the flipping and rolling of the material inside the drum, the materials stuck in the sieve holes can be ejected, preventing the sieve holes from getting clogged.

Features

1. The sieve holes are not prone to clogging;

2. It operates smoothly with low noise;

3. The structure is simple and maintenance is convenient;

4. The entire machine has high reliability and requires less initial investment;

5. It uses specially designed sieve screens, with high screening efficiency and long service life.

Technical Parameter

Model | Power | Screen Diameter | Screen Length | Rpm |

| TLGT-620 | 1.5KW | 600mm | 2000mm | 24r/min |

TLGT-820 | 2.2KW | 800mm | 2000mm | 24r/min |

TLGT-1020 | 2.2KW | 1000mm | 2000mm | 24r/min |

- Previous:

Diaphragm pump

2018-02-28 - next:

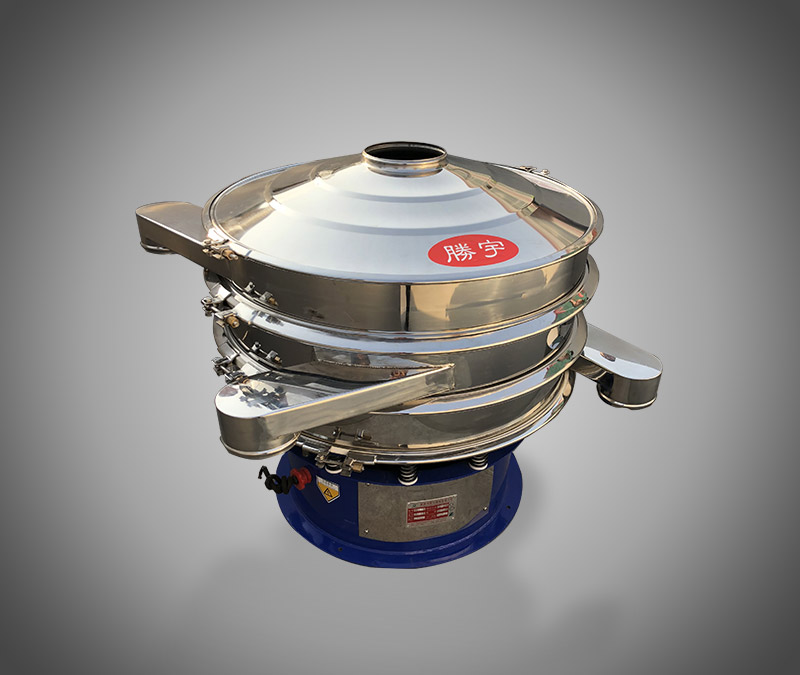

Senyou Double-deck Palm Oil Vibrating Screen

2025-10-16