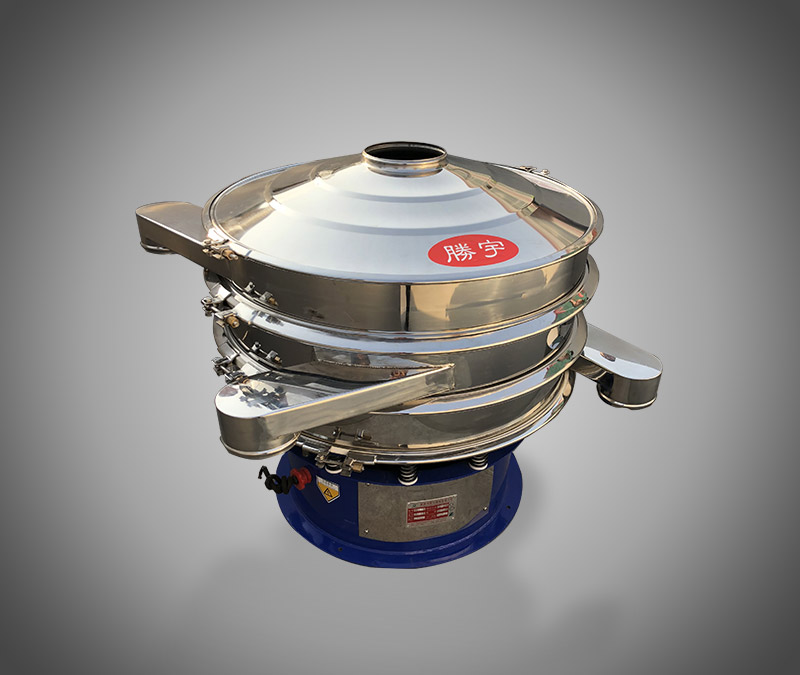

Senyou Double-deck Palm Oil Vibrating Screen

Introduction material Features Technical Parameter Message inquiryIntroduction

Senyou palm oil vibrating screen is a screening device, which works through separating solids contained in dirt crude oil by sieving / vibrating on filter media with a certain mesh size (as needed). Usually the use of vibrating screen is placed before CST (before entering COT) and after CST (in the sludge tank) .The filtering process is assisted by giving hot water as a washing machine with a temperature of 80 ℃ - 90 ℃.

material

Palm Oil Processing machine:

1. Raw material reception: collecting the FFB

2. Sterilization: the purpose is to prevent enzymes broken down, avoiding FFA content in oil further increase.

3.Threshing: separate the palm fruit from the FFB.

4. Digesting: increase the oil yield by damaging pulp cell structure

5.Pressing: separate the pulp and nut and crush the palm pulp.

5. Oil clarification: oil is clarified by the palm oil vibrate screen.

6.Kernel recovery: The separated fiber material is sent to the boiler room as fuel; the separated kernel is transported to palm kernel oil mill plant for making palm kernel oil.

Features

1. Strong and sturdy construction,widest range of materials screened.

2. Larger capacity,Less blinding,reliable,efficient ant trouble free performance.

3. Longer screen life,less power,user friendly and low maintenance.

4. Single or multiple separations,highest efficiency,Less space required.

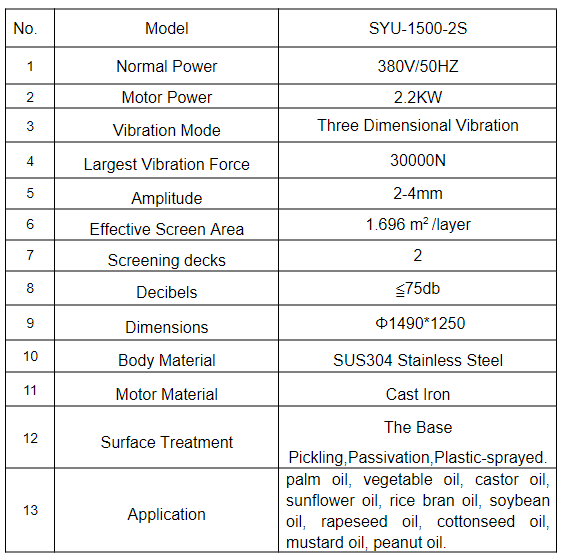

Technical Parameter

Senyou Double-deck Palm Oil Vibrating Screen---Mesh 20#-40#

- Previous:

Drum sieve

2018-04-16