Ultrasonic Vibrating Screen: Say Goodbye to Screen Clogging update time:2025-12-30 Click count:114次

Tired of your screening mesh getting clogged in minutes? Fed up with electrostatic materials sticking tightly to the screen surface, leading to extremely low screening efficiency? Or frustrated by substandard precision and drastically reduced yield of qualified products even after painstaking screening? Are these problems giving you a headache and making you feel helpless?

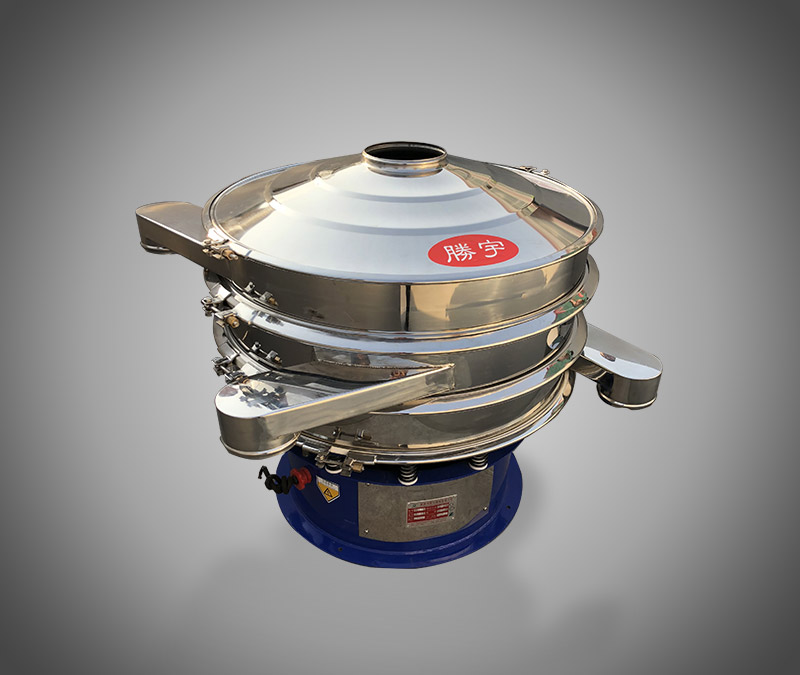

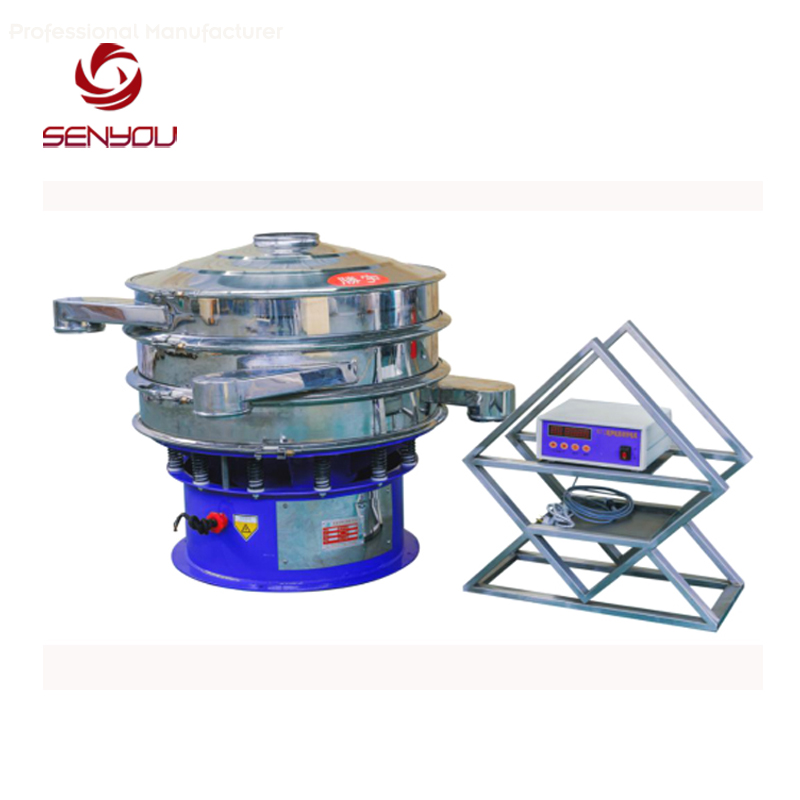

Don’t worry! Today, Xinxiang Senyou mechanical and electrical Co., Ltd. is proud to recommend a high-tech device that solves the challenges of fine screening — the Ultrasonic Vibrating Screen. Leveraging the dual power of "mechanical vibration + high-frequency ultrasonic waves", it easily overcomes the screening pain points of high-electrostatic, agglomerative and high-density materials, and has become a reliable assistant for numerous enterprises to improve production efficiency.

What are the core advantages of the Ultrasonic Vibrating Screen?

1. High-efficiency Anti-clogging, No More Frequent Cleaning: High-frequency ultrasonic vibration can "clean" the screen mesh in real time, fundamentally solving the problems of material adhesion and screen clogging.

2. Precision Guaranteed: Screening precision is increased by 70%, and output is boosted by 1–15 times, capable of handling the screening of fine particles above 400 mesh.

3. Extended Service Life, Reduced Maintenance Costs: Ultrasonic vibration reduces friction between materials and the screen mesh, significantly cutting down the replacement costs of wearing parts.

4. Intelligent and Controllable, Adaptable to Various Materials: Equipped with a digital-display ultrasonic generator, it allows flexible adjustment of frequency and amplitude, and supports automatic frequency tracking function, making it suitable for materials of different particle sizes, humidity levels and viscosities.

5. Green and Compliant, Ensuring Production Safety: Its fully enclosed design prevents dust emission, making it particularly suitable for industries with strict hygiene requirements such as food and pharmaceuticals.

With its core advantages of high-efficiency anti-clogging and precise screening, the Ultrasonic Vibrating Screen helps enterprises solve the tough problems that are difficult to tackle with traditional equipment, and has become a key part of improving production efficiency.

If your production is also plagued by issues like material agglomeration, screen clogging and insufficient precision, why not give the Ultrasonic Vibrating Screen a try? Choosing the right equipment is the key to more efficient and worry-free production!

Previous: With So Many Round Swing Screen Manufacturers in Xinxiang, What Unique Technologies Do They Adopt?

next: Senyou Square Swing Sieve: A "Versatile All-Rounder" in the Screening Industry

- 2025-12-30SayGoodbyetoScreeningChall

- 2025-12-30AutomaticPowderIronRemover

- 2025-12-30Repairandmaintenanceofsqua

- 2025-12-30WhattoDoIftheVibratingScre

- 2025-12-30Doyouwanttoknowinwhichindu

- 2025-12-30SenyouSquareSwingSieve:A"V

- 2025-12-30WithSoManyRoundSwingScreen

- 2025-12-30HowtoChooseaVibratingScree

- 2025-12-30Whatindustriesareultrasoni

- 2025-12-30Don’tUnderestimateaSquareS