Automatic Powder Iron Remover – Your Ideal Powder Iron Removal Solution update time:2026-01-27 Click count:8次

How to Solve the Problem of Iron Removal from Powder? The Automatic Powder Iron Remover is Here to Help!

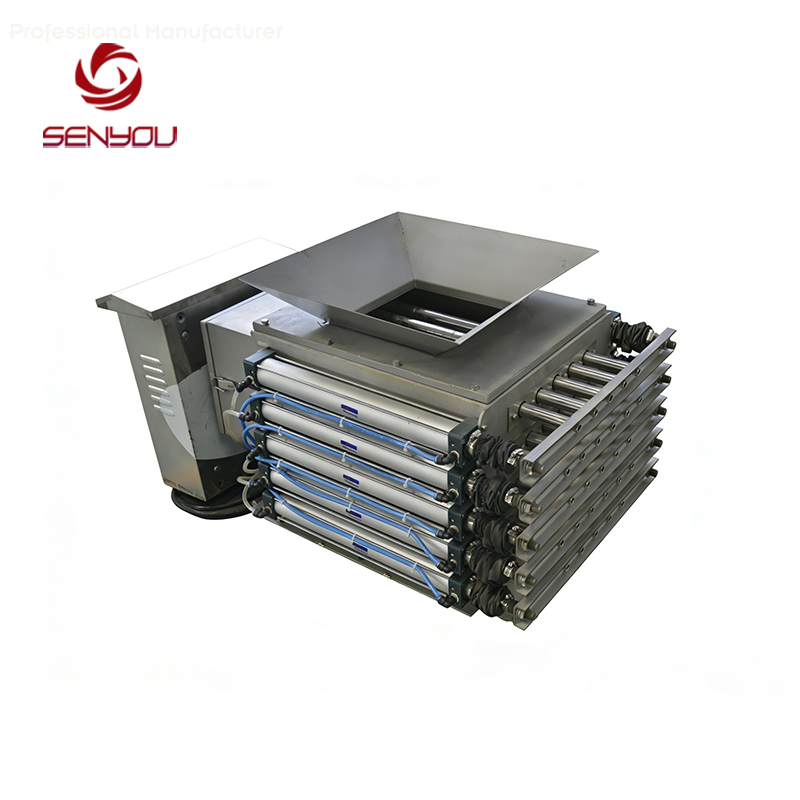

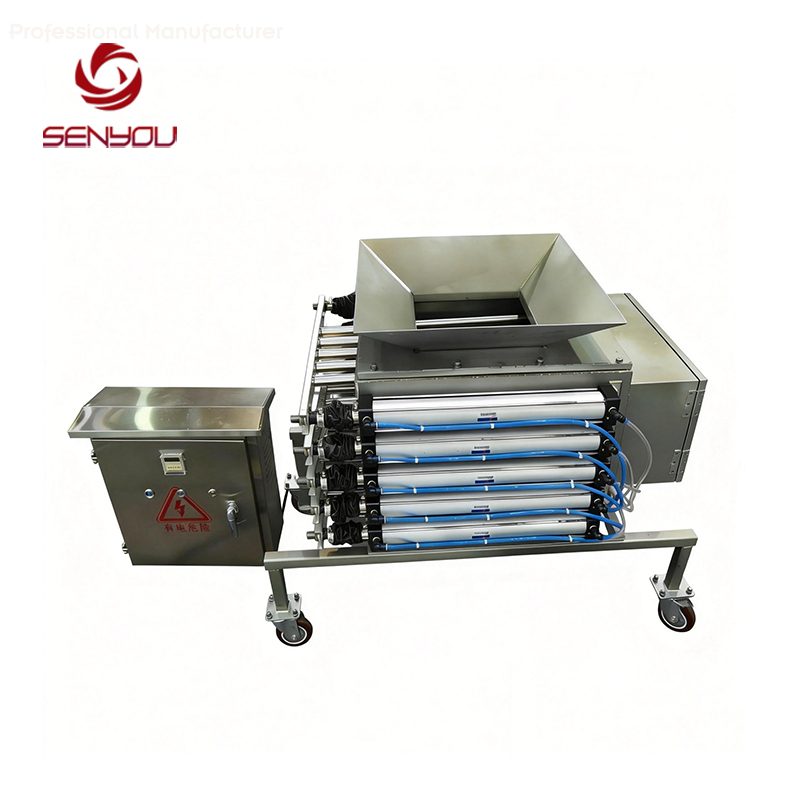

In the production processes of ceramics, mining, chemical engineering, electronics, food, pharmaceutical and other industries, the purity of powder directly determines the quality and safety of final products. Once strong magnetic iron impurities are mixed into the powder, it may not only affect the performance and appearance of products, but also damage subsequent production equipment, and even trigger serious potential safety hazards in the food and pharmaceutical industries. To address this industry pain point, the automatic powder iron remover has emerged as the times require. Relying on its core advantages of high-efficiency iron removal, intelligent control, and stable and reliable operation, it has become an essential piece of equipment for the powder purification process in various industries.

The core competitiveness of the automatic powder iron remover stems from its high-performance core configuration — it adopts a high-performance magnetic core of N50 grade or above. Compared with ordinary magnetic cores, the N50 grade magnetic core has a stronger magnetic adsorption capacity, which can accurately capture tiny strong magnetic iron impurities in the powder, with an iron removal efficiency far exceeding that of conventional industry equipment. At the same time, the high-quality magnetic core has a longer service life and does not require frequent replacement, effectively reducing the equipment's use cost and maintenance frequency, and providing a solid guarantee for enterprises to achieve long-term and stable production.

Intelligent control is another major highlight of the automatic powder iron remover. The equipment is equipped with a PLC intelligent control system, which supports the self-setting of iron discharge cycles according to customers' actual production needs.Whether it is high-frequency continuous iron discharge or customized timed iron discharge, it can accurately adapt to the production rhythms of different industries. This automatic iron discharge design completely gets rid of the tedious processes of manual on-duty and manual cleaning required by traditional iron removers. It not only saves labor costs, but also avoids problems such as incomplete iron removal or production interruption caused by human operation errors, truly realizing continuous and stable operation under unattended conditions and greatly improving production efficiency.

In response to the personalized production needs of different industries, the automatic powder iron remover supports customized services on demand. Whether it is the type and processing capacity of powder, or the space constraints of the production site, it can be accurately adapted by adjusting the structural parameters and specifications of the equipment. The equipment itself features a simple structure and easy operation, allowing operators to get started quickly without professional skill training; meanwhile, the simplified structural design reduces the failure rate of the equipment and improves operational reliability.Daily maintenance only requires basic inspection and cleaning, further reducing the operation and maintenance pressure for enterprises.

From the purification of raw material powder in the ceramic industry and the impurity removal of mineral powder in the mining industry, to the purification of reagent powder in the chemical industry and the screening of precision powder in the electronic industry, and from the safety guarantee of food material powder in the food industry to the purity control of medicinal powder in the pharmaceutical industry, the automatic powder iron remover has won recognition from enterprises in various industries by virtue of its wide adaptability, high-efficiency iron removal capacity, intelligent control system and stable operation performance.

Choosing a high-quality automatic powder iron remover is a key measure to improve product quality, reduce production costs and ensure production safety. Our automatic powder iron remover takes the N50 high-performance magnetic core as the core and is supported by the PLC intelligent control system. It also has the advantages of convenient operation, simple maintenance, low failure rate and high reliability, and can customize exclusive solutions according to the actual needs of enterprises. No matter which industry you are in or what kind of iron removal problems from powder you are facing, we can provide you with efficient and stable iron removal solutions to help enterprises achieve high-quality production upgrading.

Xinxiang Senyou looks forward to your consultation.

- 2026-01-27Repairandmaintenanceofsqua

- 2026-01-27WhattoDoIftheVibratingScre

- 2026-01-27Doyouwanttoknowinwhichindu

- 2026-01-27SenyouSquareSwingSieve:A"V

- 2026-01-27UltrasonicVibratingScreen:

- 2026-01-27WithSoManyRoundSwingScreen

- 2026-01-27HowtoChooseaVibratingScree

- 2026-01-27Whatindustriesareultrasoni

- 2026-01-27Don’tUnderestimateaSquareS

- 2026-01-27WhatDetailsShouldBeNotedWh