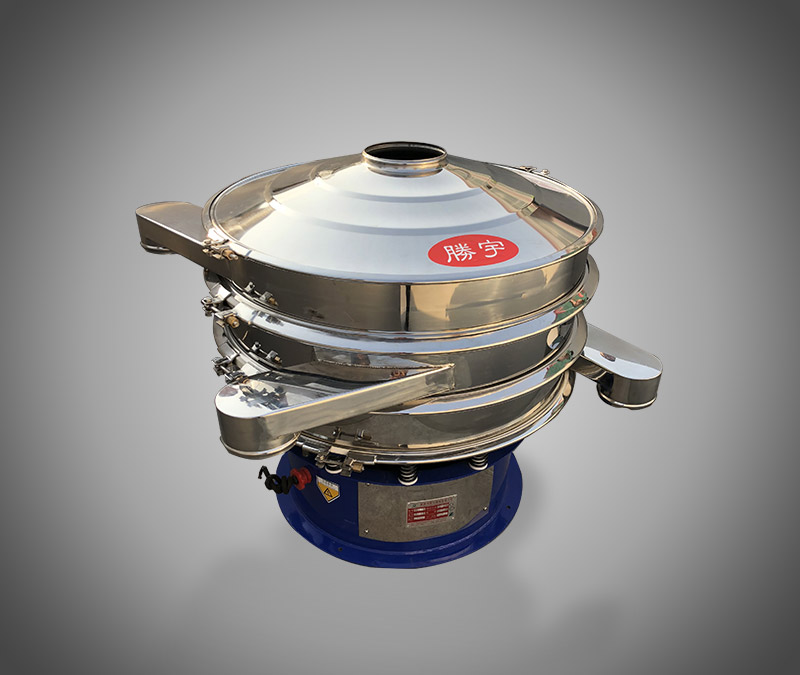

Senyou Square Swing Sieve: A "Versatile All-Rounder" in the Screening Industry update time:2026-01-04 Click count:74次

The Senyou Square Swing Sieve is a high-performance screening device launched by Xinxiang Senyou Electro mechanical Co., Ltd. With its unique design and outstanding performance, it plays a vital role in multiple industries and is hailed as a "versatile all-rounder" in the screening sector. Below is a detailed introduction to it:

Working Principle

The Senyou Square Swing Sieve adopts a manual-screening-simulated principle. Driven by an eccentric shaft drive system, the sieve box performs a composite movement in both horizontal and vertical directions, forming a spiral material movement trajectory. After entering through the feed inlet, materials slowly move toward the discharge outlet along a spiral path under the action of swing force. During this process, materials pass through the screen mesh multiple times, achieving the separation of materials with different particle sizes.

Performance Advantages

•High Screening Precision

Its unique movement trajectory and structural design enable the screening precision error to be controlled within ±0.5%, with the screening efficiency reaching over 90%—15%–20% higher than that of circular vibrating sieves of the same specification. It can meet the stringent screening precision requirements of industries such as food, pharmaceuticals and new energy.

•Large Processing Capacity

The advanced screening principle and large sieve surface area result in a high unit-area output, up to 5 times that of ordinary screening equipment, effectively improving production efficiency.

•Low Wear & Long Service Life

By optimizing the movement trajectory, the impact vibration is reduced by more than 70%, which greatly extends the service life of the equipment and decreases the need for downtime maintenance.

•Low Energy Consumption

Compared with traditional screening equipment, this device cuts energy consumption by 30%, delivering excellent energy-saving performance.

Application Fields

•Ceramic Industry

In the classification of ceramic glazes, it can reduce the standard deviation of particle size distribution and improve the product yield rate. Its modular design also supports quick screen mesh replacement, shortening the single mesh replacement time to 5 minutes and enhancing production flexibility.

•Chemical Industry

It ensures a more stable screening process and higher screening efficiency, and can be used for powder separation in the chemical industry.

•New Energy Industry

It is also applicable for particle size classification of new energy materials such as lithium carbonate and lithium hydroxide.

Previous: Ultrasonic Vibrating Screen: Say Goodbye to Screen Clogging

next: Do you want to know in which industries ultrasonic vibrating screens are applicable?

- 2026-01-04SayGoodbyetoScreeningChall

- 2026-01-04AutomaticPowderIronRemover

- 2026-01-04Repairandmaintenanceofsqua

- 2026-01-04WhattoDoIftheVibratingScre

- 2026-01-04Doyouwanttoknowinwhichindu

- 2026-01-04UltrasonicVibratingScreen:

- 2026-01-04WithSoManyRoundSwingScreen

- 2026-01-04HowtoChooseaVibratingScree

- 2026-01-04Whatindustriesareultrasoni

- 2026-01-04Don’tUnderestimateaSquareS