What to Do If the Vibrating Screen Mesh Is Clogged? Three Tips to Solve the Problem Easily! update time:2026-01-17 Click count:26次

A clogged mesh on a vibrating screen will directly reduce production capacity, cause material waste, and even force production shutdowns for cleaning. This is especially troublesome in industries such as graphite, silicon carbide, and powder processing—either there is a risk of material contamination during mesh cleaning, or hard particles get stuck in the mesh and are difficult to remove. It’s really a headache!

Don’t panic! Today, XINXIANG SENYOU MECHANICAL AND ELECTRICAL Co., Ltd. shares three highly practical tips with you. They don’t cost a fortune, are easy to operate, and can easily solve the mesh clogging problem!

Tip 1: Adjust Equipment Parameters to Reduce Mesh Clogging from the "Source"

In many cases, mesh clogging is not caused by inferior equipment, but by incorrect parameter settings! The vibration frequency, amplitude, and screen inclination angle of the vibrating screen directly affect the material screening speed and mesh penetration rate.

Operation Method:

i. For coarse-grained materials in the powder processing industry (such as quartz sand, foundry sand): Increase the amplitude and appropriately reduce the frequency. Use strong impact force to make particles pass through the mesh holes. The screen inclination angle can be adjusted to 20°–25° to prevent the accumulation of large particles.

Key Reminder:

Adjust parameters gradually during testing. Avoid excessive one-time adjustments that may cause abnormal equipment noise or material splashing.

Tip 2: Install Mesh Cleaning Devices to Enable "Self-Cleaning" of the Screen Mesh

If mesh clogging persists after parameter adjustment, it is most likely that the screen mesh lacks a "cleaning assistant"! Selecting the right mesh cleaning device according to materials in different industries can keep the screen mesh unobstructed at all times.

Operation Method:

i. For the powder processing industry (hard particle materials): Install a bouncing ball mesh cleaning device under the screen mesh. The impact of bouncing balls during vibration will shake out sand particles stuck in the mesh holes. It is low-cost, highly effective, and can be installed by workshop technicians within ten minutes.

Key Reminder:

Choose wear-resistant rubber bouncing balls to avoid material contamination caused by worn ball fragments. Regularly inspect the circuits of ultrasonic cleaning devices to prevent malfunctions in enclosed environments.

Tip 3: Pre-Treat Materials to Reduce Mesh Clogging Probability from the "Inlet"

Sometimes the root cause of mesh clogging lies not in the equipment, but in the materials themselves! For example, materials with excessively high humidity that form clumps, or those containing large particle impurities, will directly lead to mesh blockage.

Operation Method:

i. Control material humidity: Fine powder of new energy anode materials with humidity exceeding 5% tends to form clumps and clog the mesh. Humidity can be reduced in advance through drying equipment. In the powder processing industry, if materials are fed on rainy days, install a water removal device in front of the silo to prevent wet sand from sticking to the mesh.

ii. Add a pre-screening process: Install a small rotary screen or linear screen before the vibrating screen to sift out large particle impurities in the materials first (such as stones in sand powder, clumps in graphite). This reduces the screening pressure on the main screen and avoids mesh clogging from the source.

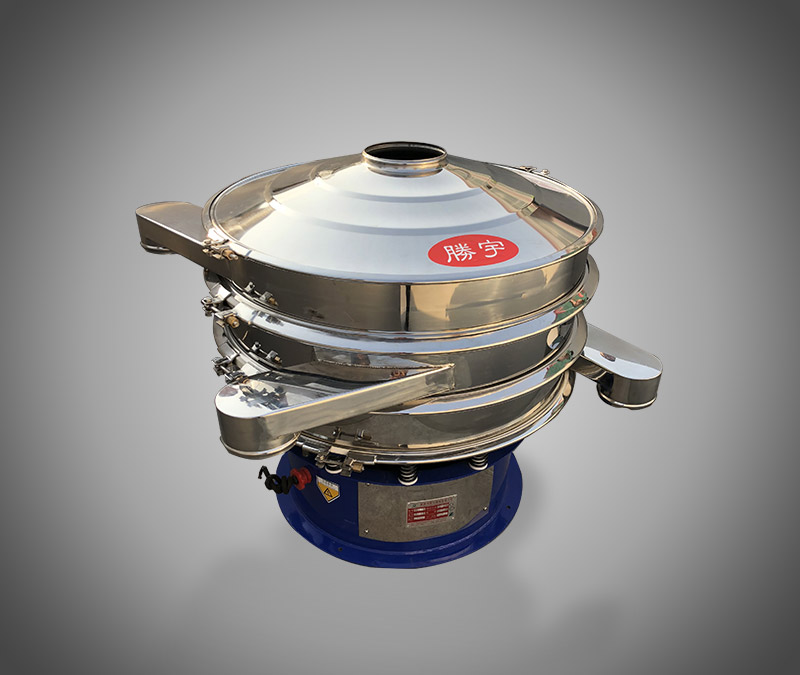

Based on the material characteristics of different industries, Xinxiang Senyou can customize special anti-clogging vibrating screens, equipped with exclusive mesh cleaning devices and parameter settings, to eliminate mesh clogging problems from the equipment design stage!

- 2026-01-17Repairandmaintenanceofsqua

- 2026-01-17Doyouwanttoknowinwhichindu

- 2026-01-17SenyouSquareSwingSieve:A"V

- 2026-01-17UltrasonicVibratingScreen:

- 2026-01-17WithSoManyRoundSwingScreen

- 2026-01-17HowtoChooseaVibratingScree

- 2026-01-17Whatindustriesareultrasoni

- 2026-01-17Don’tUnderestimateaSquareS

- 2026-01-17WhatDetailsShouldBeNotedWh

- 2026-01-17Whataretheadvantagesofthec