What are the advantages of the circular vibrating screen over the ordinary one? update time:2024-09-30 Click count:329次

Do you know what advantages the circular vibrating screen has over the ordinary circular vibrating screen?

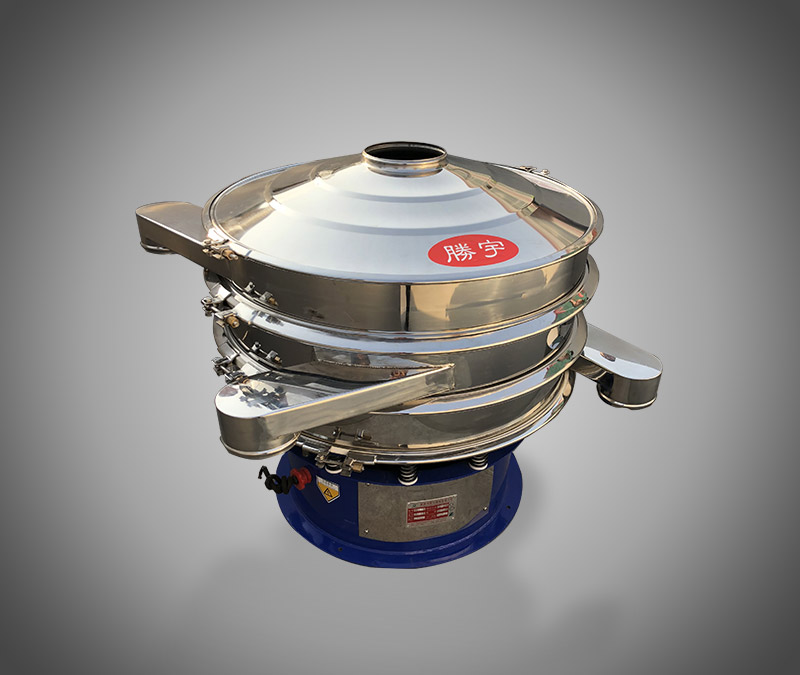

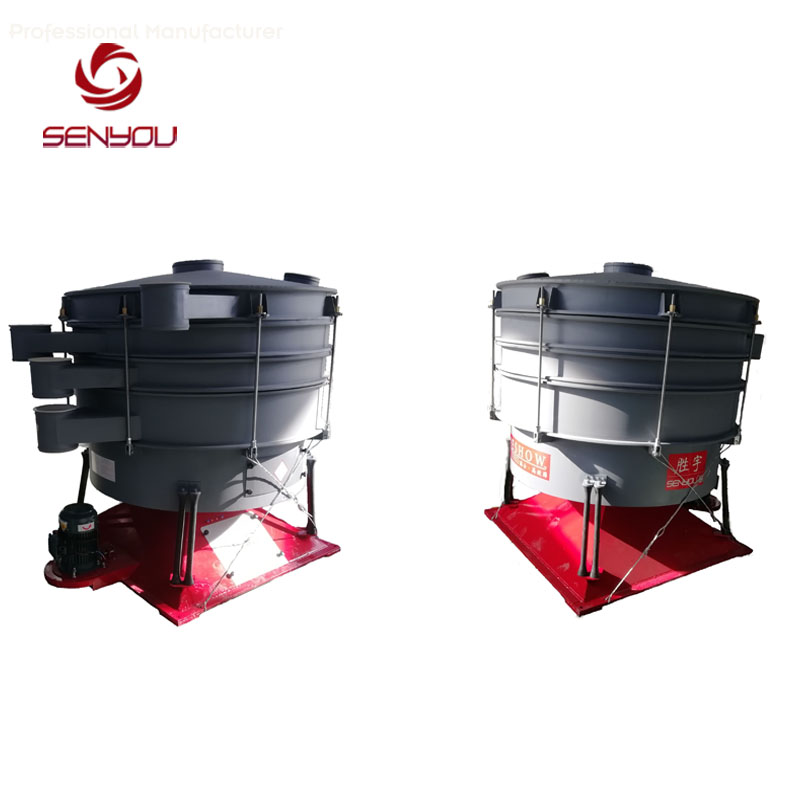

XINXIANG SENYOU MECHANICAL AND ELECTRICAL Co., Ltd. leads everyone to acquire more knowledge. Compared with the ordinary circular vibrating screen, the core advantages of the circular swing screen lie in aspects such as screening efficiency, material adaptability, equipment wear and tear, and operation experience. It is a screening equipment optimized for fine, easily clogged mesh, and easily damaged materials. The specific advantages are as follows:

1. Higher screening efficiency and more stable processing capacity

※ The ordinary circular vibrating screen achieves material stratification through high-frequency and small-amplitude vibration. The materials move in a circular jumping motion on the screen surface, which easily leads to problems such as "material clustering" and "insufficient utilization of the screen surface". Fine powder is prone to be discharged together with the coarse material, resulting in low screening accuracy and throughput rate.

※ The circular swing screen adopts low-frequency and large-amplitude artificial-like swing motion (combining circular rotation + reciprocating swing), with the materials advancing slowly in a spiral manner on the screen surface. The screen surface utilization rate can reach over 90% (compared to only 60%-70% for the ordinary vibrating screen); at the same time, the material stratification is more uniform, and fine powder can fully contact the screen mesh, resulting in a screening efficiency 30%-50% higher than that of the ordinary vibrating screen. It is especially suitable for fine material screening with a particle size range of 80-400 mesh.

2. The materials are more compatible, reducing clogging and damage

※ Anti-clogging screen: The high-frequency vibration of ordinary vibrating screens often causes sticky and easily agglomerated materials (such as flour, graphite powder, and traditional Chinese medicine powder) to get stuck in the sieve holes, requiring frequent shutdown for cleaning; the low-speed swaying and gentle throwing motion of the swing screen can enable the materials to achieve a "self-cleaning" effect on the screen surface, significantly reducing the probability of clogging and allowing continuous operation for several hours without the need for cleaning.

※ Material protection: The high-frequency impact of vibrating screens often causes damage to brittle materials (such as candy particles, chemical crystals, and glass sand) or heating and deformation of heat-sensitive materials (such as plastic particles); the gentle movement of the swing screen can reduce the material damage rate by more than 80%, making it more suitable for fragile, heat-sensitive, and easily agglomerated materials.

3. Low equipment wear and lower operating costs

※ Long lifespan of wear parts: The vibration motors, springs, and screen meshes of ordinary vibrating screens are subjected to high-frequency impacts, resulting in high failure rates of the vibration motors and a typical replacement cycle of 1-2 weeks for the screen meshes; The driving method of the swing screen is a low-speed eccentric shaft, with smaller vibration impacts, and the screen mesh lifespan can be extended to 1-3 months, and the failure rate of core components such as the vibration motor is reduced by more than 60%.

※ Lower energy consumption: The operating speed of the swing screen is only 100-300 r/min (while ordinary vibrating screens can reach above 1000 r/min), under the same processing capacity, the energy consumption is 20%-40% lower than that of ordinary vibrating screens.

4. More stable operation, better operation experience

※ Lower noise: Ordinary vibrating screens tend to generate 75-85 dB of noise due to their high-frequency vibration. In contrast, the rocking screen operates at a lower noise level of 60-70 dB, which complies with environmental protection requirements in workshops and reduces noise interference for operators.

※ Simple installation and maintenance: The rocking screen has a small vibration amplitude and requires a low installation foundation (no need for heavy concrete base), and its structure is simple. Daily maintenance only involves checking the eccentric shaft and screen mesh, which is more convenient compared to the complex maintenance of vibrating screens.

5. More precise classification, suitable for multiple specifications of screening

※ The rocking screen can be equipped with multiple layers of screen meshes. Combined with the spiral advancing trajectory, different particle size materials can be classified more clearly, with a classification accuracy 10%-20% higher than that of ordinary vibrating screens. It is suitable for scenarios where multiple specifications of finished products need to be screened simultaneously (such as mineral classification, food powder classification).

Have you known the advantages of the circular vibrating screen? Follow our company to learn more information!

Previous: Congratulations on the success of our company's website construction

next: What Details Should Be Noted When Purchasing a Square Swing Screen?

- 2024-09-30Repairandmaintenanceofsqua

- 2024-09-30WhattoDoIftheVibratingScre

- 2024-09-30Doyouwanttoknowinwhichindu

- 2024-09-30SenyouSquareSwingSieve:A"V

- 2024-09-30UltrasonicVibratingScreen:

- 2024-09-30WithSoManyRoundSwingScreen

- 2024-09-30HowtoChooseaVibratingScree

- 2024-09-30Whatindustriesareultrasoni

- 2024-09-30Don’tUnderestimateaSquareS

- 2024-09-30WhatDetailsShouldBeNotedWh